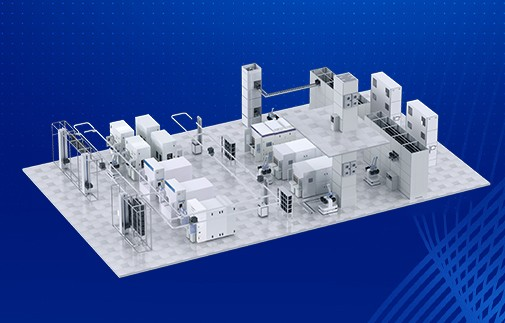

In recent years, the semiconductor industry has increasingly turned to automation and intelligent solutions to optimize production workflows. PassionIOT has established itself as a provider of comprehensive semiconductor solutions, offering systems that integrate smart storage, automated handling, and process management to meet the demanding requirements of wafer and chip production. They focus on ensuring material traceability, precision handling, and seamless integration with existing production lines.

Streamlined Semiconductor Manufacturing Solutions

One of the key advantages of PassionIOT is their expertise in semiconductor manufacturing solutions. They design systems such as the Smart Vertical Carousel and Smart Vertical Lift Module to enhance storage efficiency while maintaining a controlled environment for sensitive components. Their SMD smart warehouse solutions provide real-time inventory tracking, reducing the risk of errors in component delivery. By automating material handling processes, they help semiconductor manufacturers minimize downtime and optimize operational performance across complex production lines.

Integrating Smart Storage and Workflow

Their approach to semiconductor solutions emphasizes the integration of vertical storage systems, automated guided vehicles, and warehouse management software. This integration allows for continuous monitoring and adjustment of material flow, ensuring that production lines receive components precisely when needed. By reducing manual intervention, they not only improve efficiency but also enhance safety and accuracy in high-precision environments. Clients benefit from scalable systems that can be adapted to various semiconductor manufacturing stages.

Conclusion

Overall, PassionIOT provides robust semiconductor manufacturing solutions that cater to the needs of modern production facilities. Their combination of automated storage, real-time monitoring, and process integration supports manufacturers in achieving greater productivity and consistency. By implementing these intelligent systems, companies can streamline workflows, improve material management, and maintain the high standards required in semiconductor production. Their solutions demonstrate a practical approach to enhancing operational efficiency in a specialized and technically demanding industry.